已经有次观看 wencong在2013-07-08发布

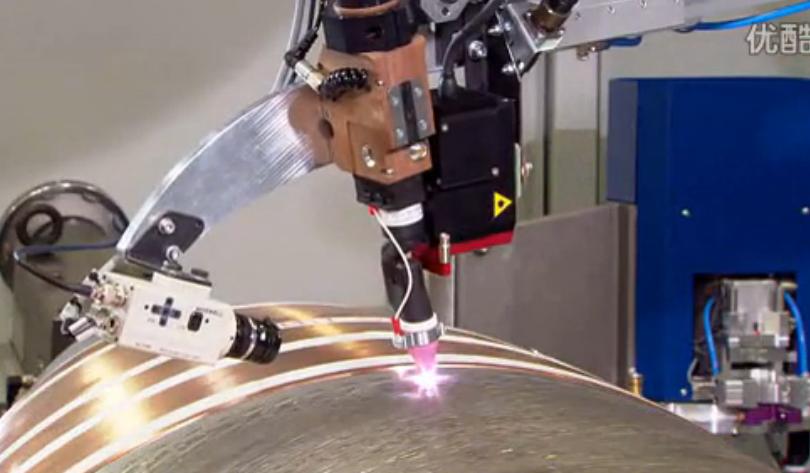

简介:The first step: the strip through the die elongated pipe

Step two: segmentation, typically 400mm or 60mm long

The third step: clear, drying, filling, sealing

Fourth step: testing, packaging, storage

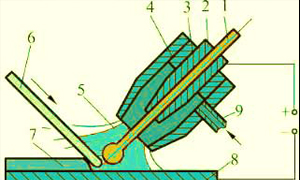

Note: 1, the matrix preheat; 2, the flame size; 3, welding distance; 4, electrode angle.

Welding process in strict compliance with: oxygen and acetylene bottles can not be put together in order to prevent dangerous!

Divided by the use of bullet holes and the holes hammer hammer; according to the use of spray ball peen hammer and a piece.

Step two: segmentation, typically 400mm or 60mm long

The third step: clear, drying, filling, sealing

Fourth step: testing, packaging, storage

Note: 1, the matrix preheat; 2, the flame size; 3, welding distance; 4, electrode angle.

Welding process in strict compliance with: oxygen and acetylene bottles can not be put together in order to prevent dangerous!

Divided by the use of bullet holes and the holes hammer hammer; according to the use of spray ball peen hammer and a piece.

视频相关评论

loading...